Chain Moorings Damage Sea Bed

Chain Mooring Slash Circle Demo

Elastic makes a better mooring!

Elastic Moorings Overview

- Life Expectancy 15+ years

- Shock Load reduced by Elastic

- Corrosion factor nearly eliminated

- No chain replacement costs

- Floating downline preserves sea bed and marine life

Environmental Conservation

Environmentally Friendly Elastic Moorings

The StormSoft™ Elastic Mooring System, connected to an adequate anchor, floats above the seabed to reduce or eliminate raking of the seabed, improving restoration of environmentally sensitive eelgrass by minimizing the typical 3-to-1 bottom-raking footprint.

Many harbors incorporating conservation moorings and eelgrass restoration projects specify elastic moorings for ecological reasons alone.

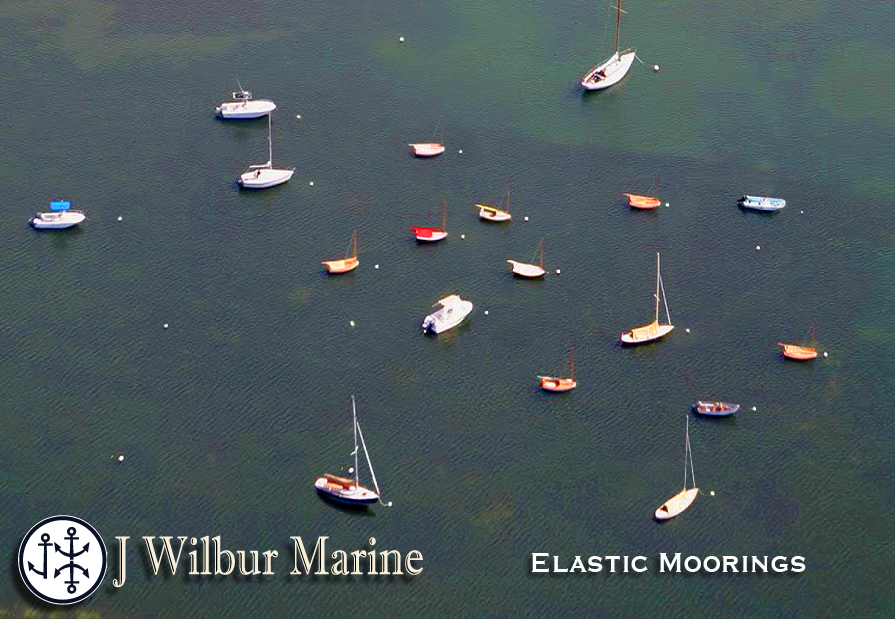

Above: Aerial photo of "crop circles" resulting from raking of sea floor vegetation and marine habitat. Remedied by use of StormSoft elastic mooring rodes.

StormSoft Elastic Moorings

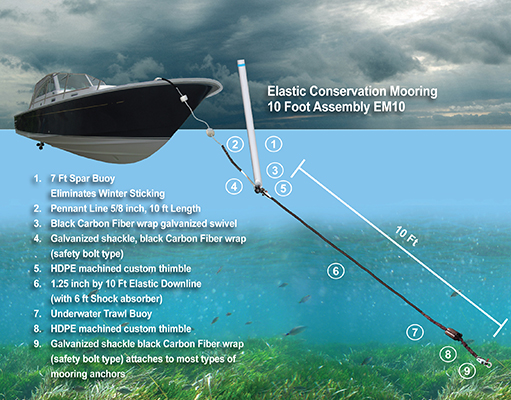

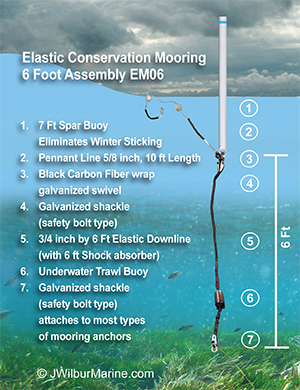

STORMSOFT™ Elastic Mooring Downline

- 100% Polyester Shell

Braided high strength 3-in-1 strand – does not absorb water and retains 100% of its dry strength. - Rubber Shock Absorber

As tension increases, the rubber shock absorber is both compressed and stretched so that movement of the boat is gradually arrested without the stress to the cleats.

Industrial rubber multi-strand cords allow limited stretch to absorb shock loads created by storms, surges or boat waves. - Braided Polyester Core

Continuous inner core of 100% braided polyester maintains position of the shock absorber. - Heavy Duty Thimbles

Thimbles are available in:- Custom machined HDPE (high density polyethylene)

- Hot-dipped galvanized

- Stainless steel

- Standard Length

1 1/4” by 10’ containing a 5 ft shock absorber.

For water depths from 7 to 15 feet.

Tensile strength starting at 24,000 lbs. - Alternate Length

3/4” by 6’ containing a 3 ft shock absorber.

For water depths from 4 to 10 feet. - Underwater Float

Keeps down line off the sea floor.

| SIZE | TENSILE STRENGTH | Includes |

| 1 1/4”D x 10’ L | 24,000# Boats up to 50 ft |

Pennant 3/4" 12 ft Length, Spar Buoy |

|

3/4"D x 6' L |

Boats up to 29 ft | Pennant 5/8" 10 ft Length, Spar Buoy |

*Spring 2017 Installation Discounts may apply in some locations.

See Shop.JWilburMarine.com

StormSoft Reduces Boat Damage

The StormSoft™ Elastic Mooring system is a more sensible alternative to traditional ball and chain moorings.

Simply put, elastic moorings nearly eliminate the severe stresses and abrupt motions of vessels anchored with chain. In extreme weather, elastic mooring systems expand up to 30% of the slack length to eliminate the destructive jerking motion typical of taut, inflexible chain moorings. Frayed mooring lines are the single most common cause of boats breaking free.

Mooring lines continuously chafe against cleats, chocks, fittings because water is in constant motion.

Over time, chafed lines may become too weak to secure the boat during the next big storm.

Elastic mooring lines give and take, reduce chafing and extend line life up to 15 years, eliminating frequent replacement expense.

Carbon Fiber Wrap

J Wilbur Marine thimbles, shackles, swivels and assemblies are carbon-fiber wrapped around galvanized steel to resist wear and corrosion. Originally designed for military use, our adhered carbon fiber wrap endures high salinity and even extreme temperatures, high or low, and costs less than brittle stainless steel.